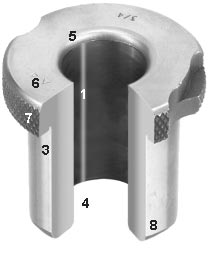

| 1.

Anti-galling process creates a

super finish which increases the

life of both the drill and the

bushing

2.

Steel: Our bushings are manufactured

from either C1144 Stress proof

steel or other high carbon steels

known for their long wear and

stability. Special materials such

as tungsten carbide, 52100 steel,

300 & 400 series stainless

steel, plus A2, D2, D3, M2, and

M4 tool steels and bronze are

also available

3.

Our bushings feature a two-directional

undercut and are ground square

to allow the bushings to fit flush

on top of the jig.

4.

Our bushing feature an inside

chamfer which improves chip control

and reduces tool wear. |

|

5.

Blended radius at drill entrance

improves proper drill entry and

alignment which prevents tool

wear and breakage.

Hardness: Bushings are heat treated

to Rockwell C62-64.

6.

For quick and proper identification,

all bushings are clearly stamped

with SIZE and TRADEMARK.

7. Slip fixed renewable (SF) bushing

heads are knurled which improves

operator handling when installing

and removing bushing from jigs

or fixtures.

8. Chamfers on the O.D. exit end

of our bushings eliminate peening

which permits easy entry and removal.

|